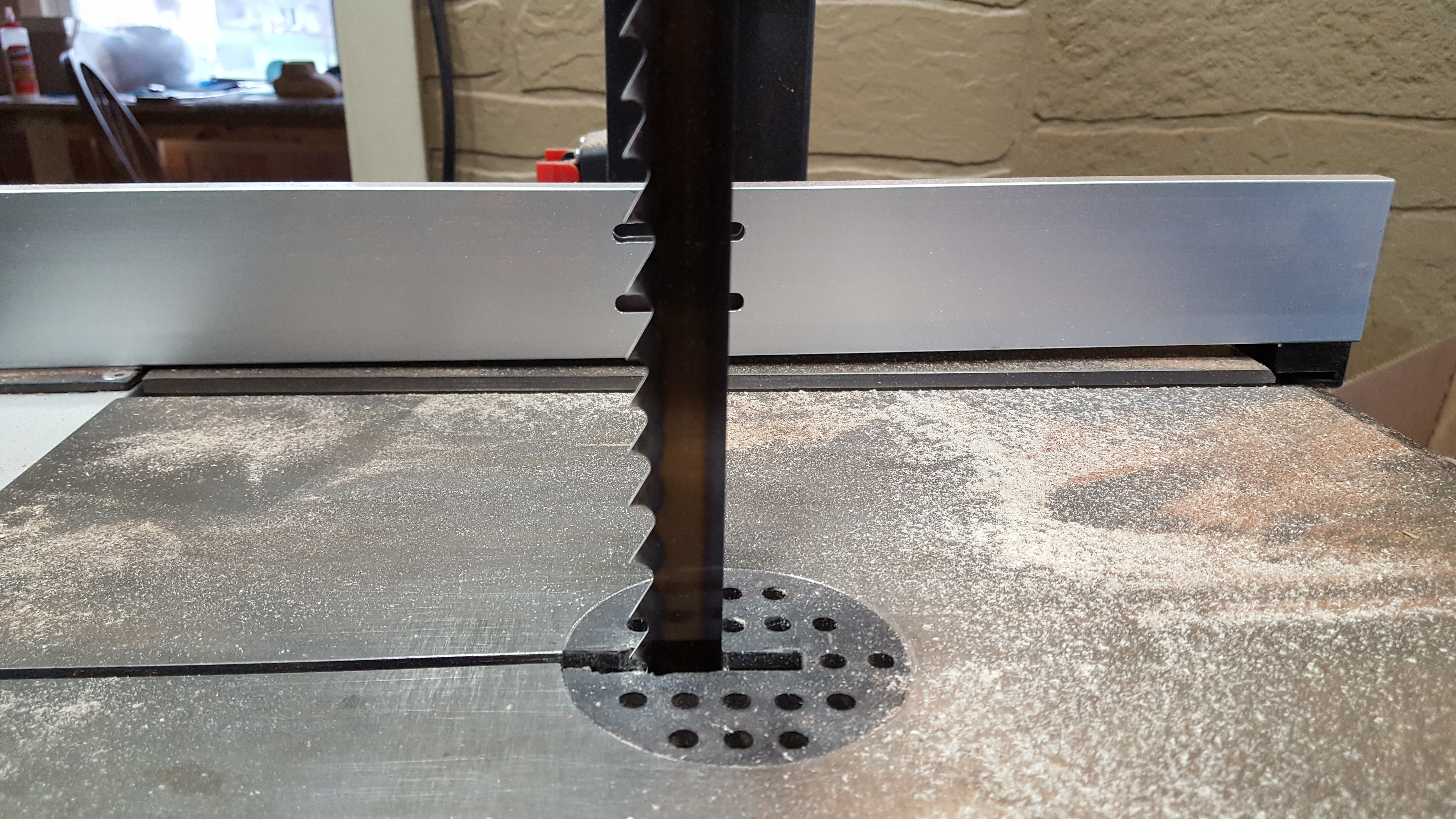

This past summer I spent some time and money improving my setup for resaw work, specifically for resawing tops and back and side sets. I want to share a simple alteration that had a pretty significant impact on the quality of my cuts: That is; purchasing a variable pitch bandsaw blade as opposed to a regular constant pitch blade.

As far as my own experience and research on the matter indicates, there is no reason to even consider a constant pitch blade when a variable pitch blade of the same size and quality exists. In fact, the availability of these blades is the only downside. They are a little harder to find.

So what is a variable pitch blade?

The most important consideration when buying a bandsaw blade, aside from size, is the TPI. TPI stands for Teeth Per Inch. The lower the TPI the better the blade is at evacuating wood debris because the debris is carried out via the large gullets between the teeth. This means that with less TPI you can resaw wider material. This is, of course, necessary for resawing the top and back plates. The drawback of a blade with less TPI is that it leaves a coarser cut.

A blade with more TPI will have a cleaner cut but, with smaller gullets, it doesn’t effectively remove large amounts of wood debris as it cuts. So it cannot handle wider boards.

Enter the variable pitch blade. A variable pitch blade alternates it’s TPI. So on a single blade you have a section of less TPI with large gullets for clearing out wood debris followed by a section of greater TPI for cleaning up the cut.

My new 3/4″ variable pitch blade handles wide boards just as well, if not better, than my old 3/4″ constant pitch blade; with the same speed of cut and without bogging down.

But now the results are far cleaner than they were with my old blade, which means that I save a lot of time planing or sanding things smooth, and I save material too because I know I can afford to make cuts closer to my intended dimensions.

There’s something else that I wasn’t expecting from this blade. The cut is SO quiet! It’s like a kitten purring. Originally, I thought this was just because I shelled out a little more money for a premium blade, and the higher quality metal of the blade somehow made it run with less noise.

But rather, I found through a little research online, that constant pitch blades can develop a flutter due to harmonic vibrations, whereas a variable pitch blade breaks up the pattern of the blade and to a large degree mitigates the problem.

My source for this is Lori Balkus’s blog here. Check it out:

http://bandsawblog.com/variable-pitch-bandsaw-blades/

Lastly, I want you all to know that the variable pitch blade cost me just as much as the constant pitch blade of the same quality and size. This is why I call it a “No-brainer.” I’ve been using the new blade for about 6 months now and I’m completely sold on the concept.

I’m surprised I don’t see more people in the hobbyist woodworker and guitarmaker space using these blades. I assume this is because many are still using economy blades from department stores. Variable pitch blades are not available from those suppliers, atleast not yet. There are many reasons to upgrade from the economy blades to a premium. This is just another reason to do it.

Anyway, here is the takeaway:

If you intend on upping your game and getting a premium blade for your resaw work, get a variable pitch blade! It’s a no-brainer!

Want more of this? Subscribe below for Weekly Guitar Making Tips from DIY Guitarmaking

Want to really learn more!? Take a class with Eric Schaefer and build your own guitar in 8 days!

Or Join The Online Guitar Building School